Ceramic and Cermet in High-Tech Luxury Watches

When we covered the broad topic of ceramic in 2020, it was still in the midst of the pandemic. At the time, we surmised that a future that involved much more vigorous hand-washing and increased personal hygiene awareness was the perfect setting for ceramic watch cases. Nothing proclaims cleanliness quite like ceramic; it is a material that projects a sort of eternal newness. In an era that celebrates and obsesses over longevity gurus and clinical scientists such as Bryan Johnson and Dr. David Sinclair (respectively), ceramic seems like a good fit.

One brand that never tires of talking up the virtues of ceramic is Rado, with CEO Adrian Bosshard always taking a moment to remind anyone who will listen that the material is the key to success at his brand. “Our top priority is to continue to talk about the many advantages of high-tech ceramic…” Bosshard told EuropaStar in 2023. The other great evangelists for ceramic in watchmaking are Hublot, IWC and Omega, all three of which offer the most exciting watches in this material at the level of fine watchmaking.

Blancpain is another brand at the highest level of watchmaking that makes liberal use of ceramic but, despite being part of Swatch Group alongside Rado and Omega, makes few waves about it. We think the brand should rethink this and embrace Bosshard’s full-throated approach, which extends to his feelings about other brands experimenting in Rado’s territory. “I really believe that other brands, luxury brands which are in different price segments, using ceramic is a compliment for Rado. It is underlining that we are doing something right,” Bosshard told us last year.

Read More: Rado Anatom Summer 2025 Specials in Lemon, Lime and Grapefruit

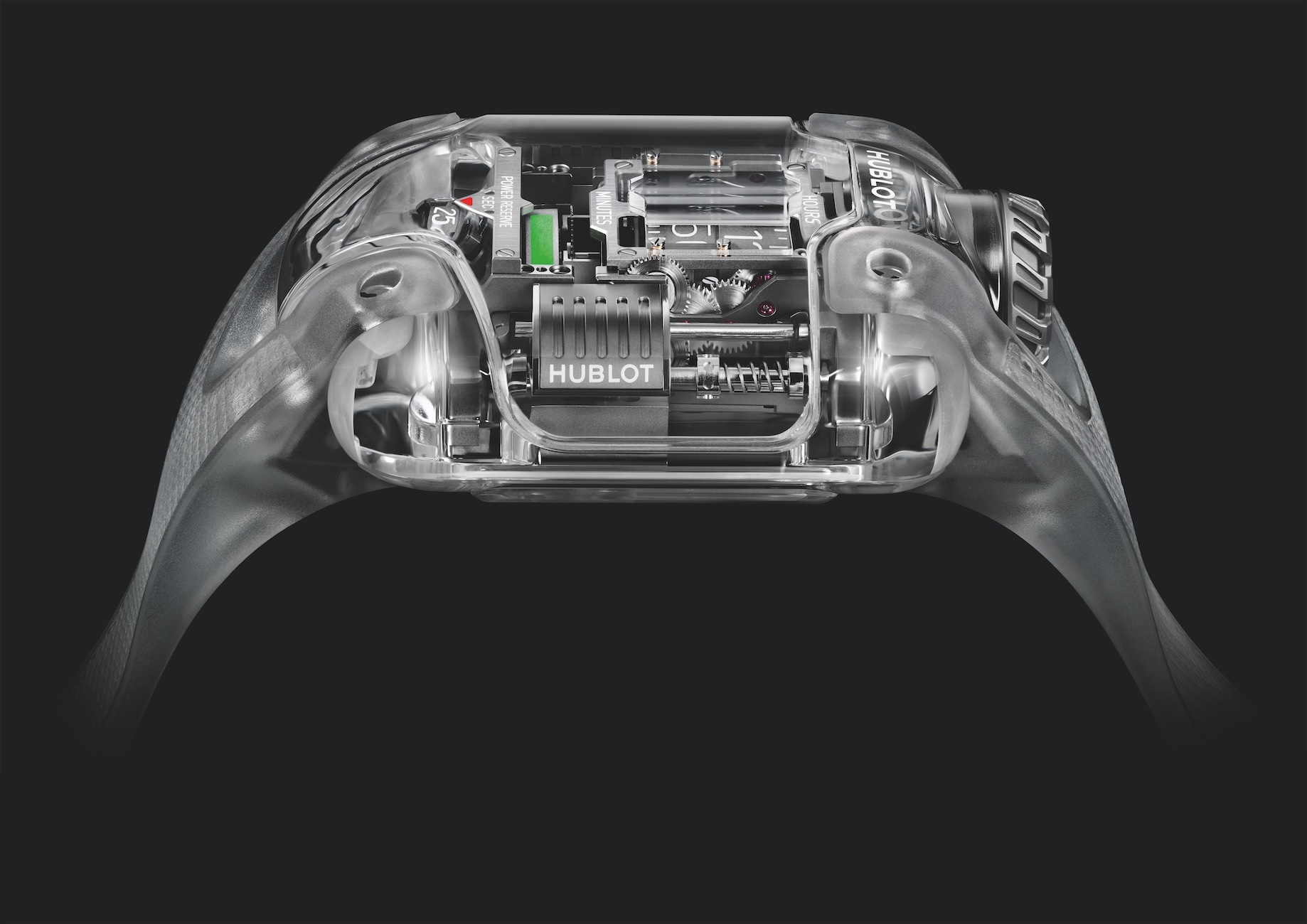

A relatively recent arrival in this arena, to everyone’s great surprise (probably), is Parmigiani Fleurier, with a new range in a combination of ceramic and metal. Called cermet for obvious reasons, this is hardly novel in general, with the material being in use since the first half of the 20th century; as noted in 2020, Omega was first to claim bragging rights with cermet in 1982; that mixture was aluminium and titanium carbide, for the record. Here is how Advanced Ceramic Materials defines it: “Cermets can be broadly classified as refractory compound alloys, hard alloys, and metal-bonded diamond tool materials. The ceramic phase in cermets is typically an oxide or refractory compound with a high melting point and high hardness, while the metallic phase mainly comprises transition elements and their alloys.” The material is a little more novel in watchmaking, with IWC already having Ceratanium in play while Hublot has its formidable Magic Ceramic and Magic Gold.

Having said all this, it is well to consider once more what constitutes ceramic anyway, as there remains confusion about this material, thanks to the association with dishware. To that end, we will reconstitute our definition from the Summer issue of 2020. The material which comes to mind when you hear the word ceramic is actually very different to the types currently being employed by brands across the watch stratosphere from Citizen to Audemars Piguet.

Ceramic is anything solid, non-metallic, inorganic and created with heat, and we call the ceramic used in watchmaking “high-tech ceramic,” as Bosshard refers to it, or technical ceramics. Technical ceramics are formulated from the purest materials to create compounds resilient enough for watch components. In general, such technical ceramic is strong and hard (see the relevant segments for more details), relative to steel, but it depends on the specific kind of ceramic and what exactly you want to measure. Zirconia, for example is about as stiff as steel but alumina is stiffer–zirconia is the toughest and strongest kind of ceramic there is (treatments and other production matters notwithstanding). Ceramic is typically pretty hard, hence the industry’s claims about “scratch-proof” or, more reasonably, scratch-resistance; zirconia clocks in at 8.5 on the Mohs scale (see ‘Hardness’).

The production method used for ceramic in the horology industry is called sintering. It is otherwise known as frittage in French, and thus watchmaking. It essentially involves applying heat and pressure to ceramic powders but without melting them. Instead, the material’s atoms become bonded (both covalent and ionic bonds are possible) together in a solid mass.

The powder is first formed into the shape of the watch’s case, before being exposed to very high temperatures (around 800ºc) under a compression of about 600 tonnes per square centimetre. After that, it can be milled and polished. What that leaves is a ceramic compound with a host of benefits over many of the other materials common to watchmaking. For one, it is incredibly hard (around 8.5 on the Mohs scale) and practically impossible to scratch. It is also almost completely inert, meaning that it will not corrode or rust, or cause allergic reactions in the same way as, say, the nickel used in some steel alloys does. In addition, it is unaffected by ultraviolet light, so it will not fade or change colour over time.

This year, high-tech ceramic has even more reason to shine, given that none other than Rolex has chosen it as a dial material, which is a first for the brand. In a way, it also reaffirms Omega and Longines’ strategies – and that of the Swatch Group but we digress. Ceramic continues to be essential to watchmakers, although full cases and bracelets in the material are likely still a ways away.

This story was first seen as part of the WOW #79 Summer 2025 Issue

For more on the latest in luxury watch reads, click here.

The post Ceramic and Cermet in High-Tech Luxury Watches appeared first on LUXUO.